Teknik Parametreler

| Maksimum Çalışma Boyutu (L*W*H)(mm) | 3000*1100 mm(Artık malzeme genişliği ≤ 60 mm) |

| Minimum Çalışma Ölçüleri (L*W) | 1800*300 mm(Artan malzeme genişliği≤60mm) |

| Çalışma Kalınlığı | 30-60 mm |

| Ana Testere Gücü | 3*5.5 kW(Φ300* Φ30) |

| Çizici Testere Gücü | 3*1.5 kW(Φ120* Φ22) |

| Maks. Hareket Hızı | 40 m/dak |

| Vakum Tutucu Konumu | Servo konumlandırma |

| İş Parçası Konumlandırma | Merkezleme |

| Çalışma Tablası Yerden Yüksekliği | 960 mm |

| Toz Çıkışı Adedi | Φ200*1 |

| Toplam Güç | 35.5 kW |

| Makine Ağırlığı | 3500 kg |

| Makine Ölçüleri | 5184*2700*2396 mm |

Ürün Videosu

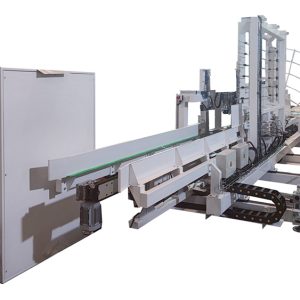

Genel Özellikler

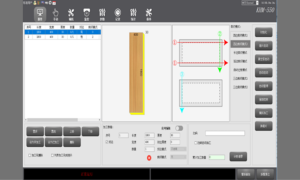

Kontrol Paneli

Görsel düzenleme ve işleme yazılımı ile donatılmış PC tabanlı akıllı kontrol sistemi.

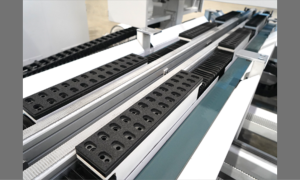

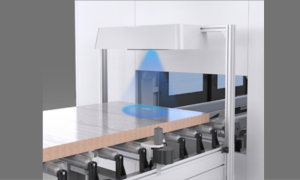

Kolonlar

Vakum tutucu tablası; kesimi panel boyutuna göre ayarlar ve çalışma tablasının zarar görmesini önler.

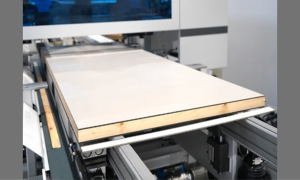

Atık Toplama Ünitesi

Otomatik olarak bant sistemiyle atık toplama yapılır.

Öne Çıkanlar

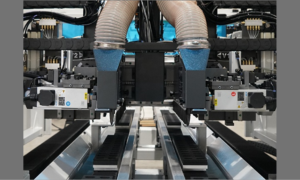

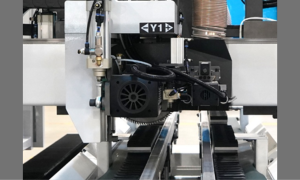

Boyuna Testere Ünitesi

Servo kontrollü, panel kalınlığına göre ayarlanabilir, hassas kesim sağlar.

Yatay Testere Ünitesi

Servo kontrollü, panel kalınlığına göre ayarlanabilir, hassas kesim sağlar.

Otomatik Tarayıcı

Kamera tabanlı barkod okuyucu sistemi.(opsiyonel)

Değerlendirmeler

Henüz değerlendirme yapılmadı.