KS-843D Önden Yüklemeli

FORMER-FQ-ZHJ2800

KE-655JHS

MACTECH-MPACK

KD-612NCSD

6 kW freze motoru: Tek yönlü veya opsiyonel dört yönlü agrega ile farklı yüzeylerde oyma ve oluk açma işlemleri yapabilir. 5 tip ATC desteği: Kaba talaş alma, frezeleme, lamello ve benzeri işlemleri daha kolay gerçekleştirir. 6 takımlı otomatik magazin: Kaba talaş ve lamello için yatay bıçak depolayabilir. Otomatik takım sıfırlama ve uzunluk ölçümü bulunur. Çift yönlü hava yüzeyli hareketli tabla: Delik konumuna göre esnek hareket ederek delme hassasiyetini artırır ve alt yüzeyde kirlenmeyi engeller. Çift konumlandırma modu: Farklı panel ölçülerinde daha hassas ve verimli konumlandırma sağlar. Bantlı konveyör toz toplama sistemi: Makine içindeki tüm tozu merkezi olarak uzaklaştırır. Simülasyon özelliği: İşlem süresi ve adımları önceden görülebilir. İşlem kayıt istatistikleri: Üretim ilerlemesi gerçek zamanlı olarak takip edilebilir.

Teknik Parametreler Ürün VideosuKD-612NH

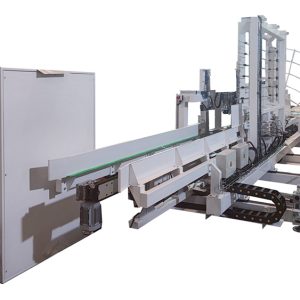

140 met/dak klamp hızı Parça boyu kontrolü Parça genişliği kontrolü Otomatik yan dayama aparatı Klamp içinden delme özelliği 35 mm minimum parça genişliği Otomatik sensörlü boşaltma konveyörü Uzatılmış kızak boyu(5000mm) ile daha hızlı işlem

Teknik Parametreler Ürün VideosuKD-612TH

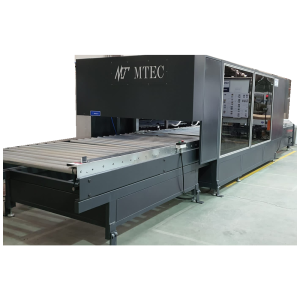

Çift matkap paketleri arasında minimum delme mesafesi 64 mm’dir. Çift tutucu ve uzun kılavuz ray sayesinde tutucu 140 m/dak hıza ulaşır; otomatik delik algılama ile tutucu değişim süresi ortadan kalkar. Tutucu hareket mesafesi 5,5 m’ye kadar çıkar; büyük paneller tek seferde işlenir ve süre kısalır. Çift yönlü hava yastıklı hareketli tabla, delik konumuna göre esnek hareket ederek doğruluğu artırır ve alt yüzeyin kirlenmesini önler. Çift konumlandırma modu, farklı panellerin daha doğru ve verimli yerleştirilmesini sağlar. Bantlı konveyörlü toz toplama sistemi tüm tozu merkezi olarak temizler. Yazılım, işleme yolunu simüle eder ve işlem süresini önceden tahmin eder. İşlem kayıt istatistikleri tutulur ve üretim süreci gerçek zamanlı izlenebilir.

Teknik Parametreler Ürün Videosu