“Delik Otomasyon Çözümleri 1” için yorum yapan ilk kişi siz olun Yanıtı iptal et

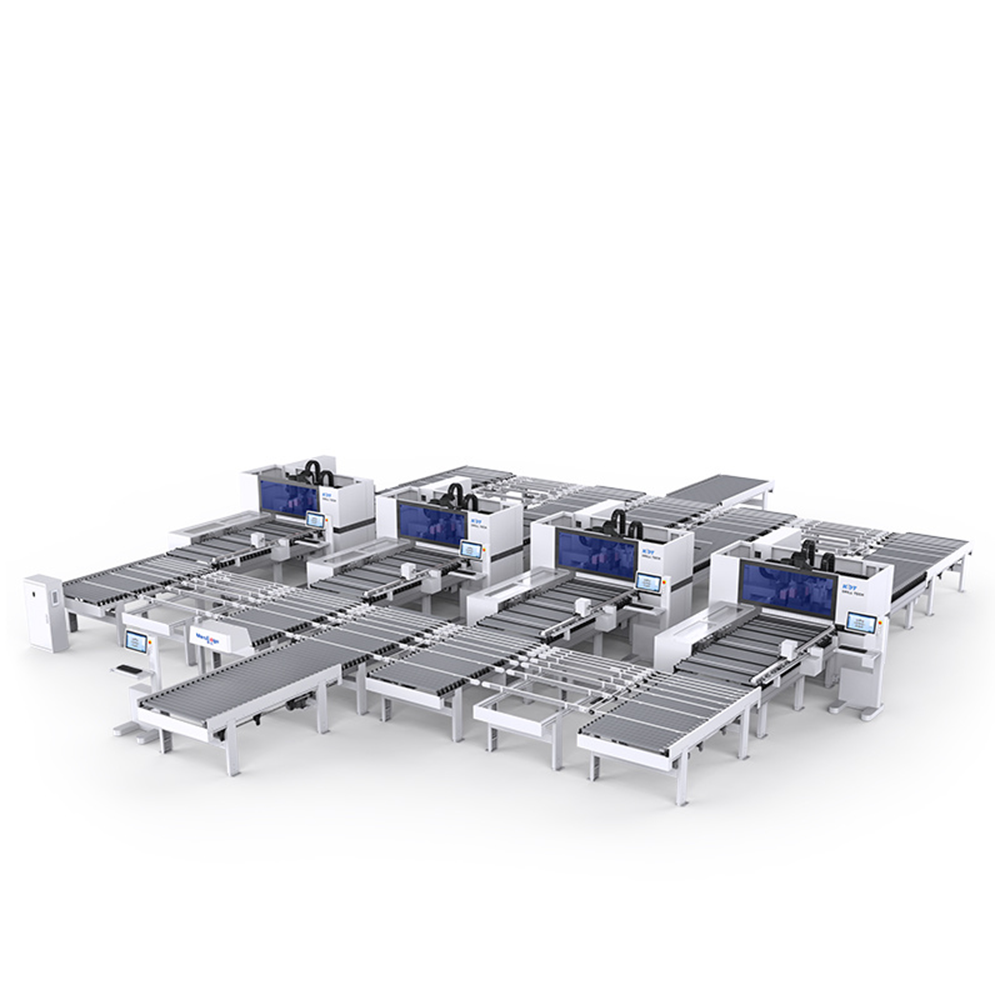

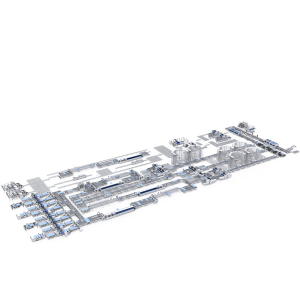

Delik Otomasyon Çözümleri 1

Kategoriler: CNC Delik Hatları, Genel

Etiketler: Üretim Hatları

İlgili ürünler

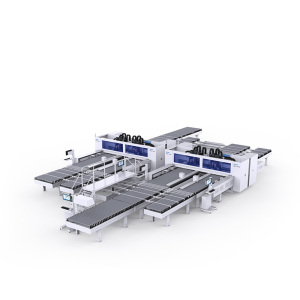

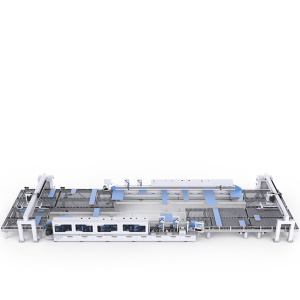

Delik Otomasyon Çözümleri 2

KDT A6 MMK213B-RR

Ürün Açıklaması

2 R+R ünitesi

Boya kullanarak ara zımparalama

Zımpara kayışının ters hareketi

Besleme konveyörünün sabit çalışma yüksekliği (hat çalışması)

Makinenin dokunmatik ekranı - kontrol paneli (kurulum, kontrol, kontrol)

Aşındırıcının, parçaların, konveyörün temizlenmesi

Parçaların vakumla sabitlenmesi

Parçaların ön ve arka kenarlarının hasar görmesine karşı koruma

Çalışma ünitelerinin elektronik frenleri

Zımpara kayışı konumunun fotoelektrik kontrolü

Teknik Parametreler Ürün Videosu

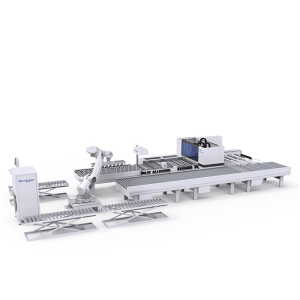

KDT PM6-1000

Ürün Açıklaması

8 bağımsız çalışma ünitesi + üflemeli parçaların temizlenmesi için şaft

Dokunmatik ekranlı PLC ile tam makine kontrolü

99 işleme programı için dahili hafıza

Verimli aspirasyon sistemi

Besleme konveyörünün sabit yüksekliği (makineyi otomatik hatta kurma imkanı)

Teknik Parametreler Ürün Videosu

KDT PX9-1300

Ürün Açıklaması

8 bağımsız çalışma ünitesi + üflemeli parçaların temizlenmesi için şaft

Dokunmatik ekranlı PLC ile tam makine kontrolü

99 işleme programı için dahili hafıza

Verimli aspirasyon sistemi

Besleme konveyörünün sabit yüksekliği (makineyi otomatik hatta kurma imkanı)

Teknik Parametreler Ürün Videosu

Değerlendirmeler

Henüz değerlendirme yapılmadı.